May 2020 SCM – Digital Business Information and Value Chains

CHALLENGES OF THE GLOBAL FOOD SUPPLY CHAIN

_______________________________________________________________________________________________

Value Chains代写 Digital Business Information and Value Chains The global food supply chain brings us exotic fresh foods from around the world.

Food habits are changing, from the rising popularity of organic products to an increased focus on sustainable packaging, while expecting exotic foods, fresh on their plates, year round, consumers continue to drive trends throughout the food and beverage industry Value Chains代写

The global food supply chain brings us exotic fresh foods from around the world. But the challenges in ensuring affordable and healthy food are enormous.

For example, while the U.S. produces the most tomatoes, Mexico accounts for 71 percent of tomato imports and Canada accounts for 27 percent. Fourteen percent of the raw buffalo milk used for mozzarella is made in Italy, while 86 percent of buffalo milk is produced in Asia. Value Chains代写

Additionally, China produces 47 percent of mushrooms across the globe, followed by the U.S., which produces only 11 percent. Fifty-six percent of our anchovies are produced in Peru, while pizza anchovies come from Argentina, Croatia, Spain and Italy.Value Chains代写

More than 11 percent of India’s spices are exported to the United Arab Emirates, the U.S., Europe and Malaysia, and 95 percent of unprocessed peppers are exported through China, India and the U.S.Value Chains代写

Furthermore, 2.5 billion pounds of beef were exported to top markets in Canada, Japan, Mexico, South Korea and Hong Kong.

In addition to the complexity of our food supply chain, the increasing demand of food coming from emerging markets, the international trade wars and political and economic uncertainties, and climate changes put a massive strain on the global food supply.Value Chains代写

The food supply chain faces six major challenges:

-

Traceability: Tracking Food in the Supply Chain

One of the biggest obstacles to full visibility of our food is the fragmented nature of the supply chain. For even simple food items there can be a huge number of actors involved, spread around the globe, and with little to no knowledge of one another’s actions.Value Chains代写

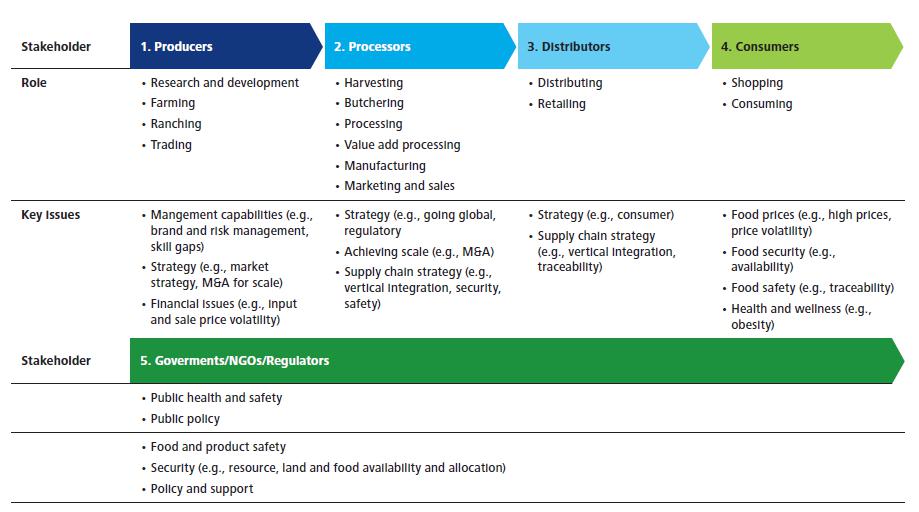

There are multiple stakeholder involved in the food value chain; this includes

- The producers that research, grow, and trade food commodities,

- The processors, both primary and value added, that process, manufacture, and market food products;

- The distributors, including wholesalers and retailers, that market and sell food;

- The consumers that shop, purchase, and consume food; as well as

- Governments, non-governmental organizations (NGOs), and regulators that monitor and regulate the entire food value chain from producer to consumer.

Very often, each organization in the food supply chain is responsible for tracing just one supply chain link:

one upstream and one downstream. With most of these companies working independently to trace their piece of the supply chain on paper, emails or through spreadsheets, the process is often slow with little to no visibility being shared outside their four walls. Yet, in order to run an efficient and transparent supply chain, stakeholders need to share accurate, real-time information with all participants.Value Chains代写

Each stakeholder has its own key issues but fragmented information and lack of communication can have a major impact on the food supply chain.

Knowledge and data sharing (e.g., food storage best practices, consumer trends, inventory levels) can improve efficiency along the value chain. In addition, greater vertical integration within the value chain (e.g., retailer private label programs) means that individual stakeholders are taking on additional roles and responsibilities Value Chains代写

An effective supply chain visibility solution together with a well developed traceability strategy allows organizations to see where each ingredient came from and where the finished product is heading. This end-to-end visibility is the key to resilient supply chains and becomes especially important when facing disruptions in the supply chain or crisis situations such as recalls.Value Chains代写

-

Transparency: Collaboration in the Foodservice Supply Chain

More than ever consumers want to know how their food was grown, handled, shipped, produced and packaged, and food companies must respond or run the risk of being left behind. It is vital that customers feel they can trust the quality and integrity of the food they are buying. Some of this desire for information has been a consequence of various well-documented food scandals.Value Chains代写

Consumers have become more educated when doing their shopping and are putting that knowledge to use to make careful and informed purchasing decisions. Over the last decade, shoppers have become increasingly health conscious and concerned about the presence of additives, artificial and genetically modified ingredients. According to Nielson, products labelled “free of additives and artificial ingredients,” grew 8 percent in 2017 while “all natural” grew 7.8 percent and “nothing artificial” grew 3.6 percent compared to the previous year.

To trace your hamburger for instance from farm to fork may involve tracing your lettuce back to the farm it was grown on (but not what happens to it before it reaches your supermarkets shelves), tracing the beef back to the cattle (with no guarantee, as seen with the horsemeat scandal, that the end product is 100% beef) and any number of logistical barriers.Value Chains代写

It is vital then that stakeholders within the foodservice supply chain prioritize communication with their suppliers, either through the implementation of traceability solutions, or the commitment to engage only with suppliers they know they can trust.

Not only is this beneficial to the end consumer, but to the food producers themselves. Close communication and collaboration means faster and better service at lower cost, and it ensures that their reputations are protected and not left in the hands of unknown and uncontrollable third parties.Value Chains代写

-

Food safety and quality

As the food supply chain becomes increasingly global to meet growing demand around the world, the risk of contamination along the supply chain rises.Value Chains代写

Some of the common causes we see that affect the quality and safety of food products which include:

- Poor storage and warehousing practices

- Delays in transportation

- Industrial sabotage

- Inclement weather

The World Health Organization estimates that almost 1 in 10 people become ill every year from eating contaminated food.

The American Center for Disease Control estimates that on average, over 300 food recalls are reported every year, which result in more than 75 million food-borne illnesses, 325,000 hospitalizations, and 5,000 deaths.Value Chains代写

Recent examples are the strawberry needles crisis in Australia in 2018; sewing needles were found embedded in a number of punnets of strawberries and this triggered a country-wide investigation or the 2018 recall of 206 millions of eggs in US over salmonella contamination fear.Value Chains代写

The financial impact of a recall is quite significant: 52% of all recalls cost over $10M and 23% cost over $30M.

In addition these incidents damage faith consumers have in their food and can lead to important future sales dropping Value Chains代写

In such a complex system it becomes necessary to move from traditional systems of centralized trust to a distributed network that enables strict monitoring and auditing.

In the event of a recall, companies can pinpoint the source of the problem and limit the recall to the affected product, instead of doing expensive “wide-net”recalls.Value Chains代写

Every stakeholder must be responsible and accountable for the sourcing, handling, and quality control of food because a food-related illness due to a mishap anywhere along the value chain can ruin a company’s reputation, even if it is not specifically at fault.Value Chains代写

-

Threat: Organized Crime and Food Fraud

When one thinks of the Mafia, olive oil is not the first thing that comes to mind.

However, in 2016 Italian police nabbed 7,000 tons of phony olive oil. The oil was from North Africa, deodorized with chemicals and rebranded as more expensive Italian extra virgin. The scam was cooked-up by organized crime.Mafia copies of fine olive oil, wine and cheese have fueled an explosion of food crime in Italy. It’s estimated to be a $16 billion-a-year enterprise. The Italians call it “Agromafia”…and it’s a scandal for a people whose cuisine is considered a national treasure.Value Chains代写

This is not just a problem for Italy either, counterfeit food and drink occurs on a massive scale throughout the whole of Europe. A joint initiative by EUROPOL and INTERPOL in 2016 led to the largest ever seizure of fake and adulterated products.Value Chains代写

The project, known as OPSON V resulted in the seizure of 11,000 tonnes of hazardous fake food and and 1,440,000 liters of altered or counterfeit alcoholic drinks across 57 countries.

In order to combat the growing threat organized crime has on our food supply, it is vital that the food and beverage industry works with the governments to be able to trace, identify and distinguish legitimate products from the counterfeits Such tracking not only prevents and deters food fraud, it can also mitigate its effects if it does happen.Value Chains代写

Companies that take steps to guarantee the authenticity of their products can build their customer base, customer loyalty and protect their brands.

Tighter Legislation: Need for Compliance to Federal Regulations and Food Safety Standards

Adhering to strict federal regulations for food product and ingredient traceability remains one of the most consistent challenges across the food and beverage industry, especially for those that continue to rely on manual data collection.Value Chains代写

There are two main acts that delineate what food manufacturers can and cannot do to remain compliant:

2001 Bioterrorism Act: This law requires food processors to be able to identify the origin of all food— including all ingredients—received by lot, code or other identifier and provide the same information to the FDA upon request within 24 hours. Both civil and criminal actions can be taken in the event of a failure to produce the information.Value Chains代写

2011 Food Modernization and Safety Act: This law gives the FDA the authority to order mandatory recalls and establish a food product tracing system. The FDA updates the act yearly to add new mandates aimed at increasing food traceability.Value Chains代写

-

Food loss and waste reduction

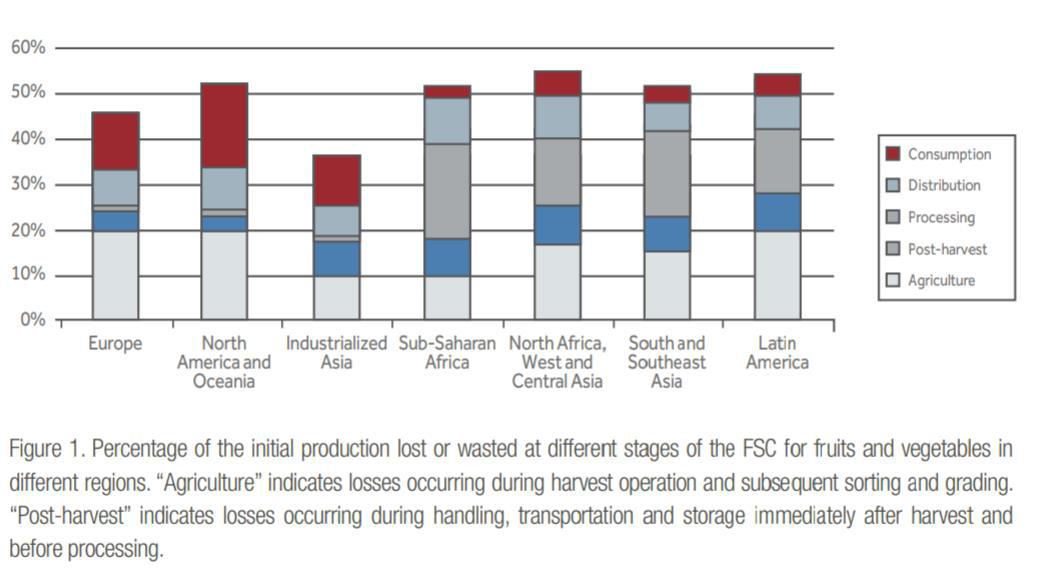

According to the FAO, an estimated 30% of the food produced for human consumption globally is lost or wasted somewhere along the food supply chain.

Food loss is mainly caused by the malfunctioning of the food production and supply system or its institutional and policy framework. This could be due to managerial and technical limitations, such as a lack of proper storage facilities, cold chain, proper food handling practices, infrastructure, packaging, or efficient marketing systems.Value Chains代写

Food waste refers to the removal from the food supply chain of food which is still fit for human consumption. This is done either by choice or after the food is spoiled or expired due to poor stock management or neglect. Food waste typically but not exclusively happens at the retail and consumer levels whereas food loss takes place at the earlier stages of the food supply chain – during production, post-harvest and processing stages.Value Chains代写

Food loss and waste have significant negative economic and environmental impacts. The value of annual food loss and waste at the global level is estimated at US$ 1 trillion.

Food loss and waste represent wastage of the water, land, energy and other natural resources used to produce food. In fact, the resources used to produce food that is eventually lost or wasted account for approximately 4.4 gigatonnes of greenhouse gas emissions (CO2 equivalent) annually, making food loss and waste the world’s third largest emitter, after only China and the United States Value Chains代写

Reference articles :

− The five Ts of global food supply Chain by Sean Crossey – The network effect

− How Technology is Changing, Challenging the Food Industry by Lisa tryson – Food Quality and Safety − Fixing the 5 big problems in the food supply chain by Jad Assad – The network effect

− The food value chain A challenge for the next century – Deloitte Report

− Real time inventory visibility for the food and beverage industry – Rfgen whitepaper − Quick Guide to Food Supply Chain Traceability – Arviem whitepaper

− Food Industry faces unprecedented supply chain challenges by Rick Pendrous – Food Manufacture − The Future of Food Traceability By William Fisher- Food safety Magazine

− Securing the Food Supply Chain: Achieving Traceability and Chain-of-Custody to Minimize Risk by James Curtis – Food logistics

− Transparency, food and the global supply chain by Stanley Chia – New food

− End-To-End Traceability: The Start of Supply Chain Safety by Dean Wiltse – Food Quality and Safety − Foods loss and waste in the food supply chain – FAO report

− The Importance of Food Traceability By William Fisher – Food safety Magazine

您必须登录才能发表评论。