Operating Procedures in Hospitality Industry

Name

Institution

Operating Procedures in the Hospitality Industry

Operating Procedures代写 The manual will provide you with orientation to perform the jobs properly, and facilitate consistency in the ···

This manual is part of prerequisite orientation to new employees in Green Bean Cafe. Every employee is required to be well acquainted with standard operating procedures. These are written instructions that document routine activities followed in this café. This manual aims to help you maintain the quality and consistency of services and standards in Green Bean Café. We take standard operating procedures seriously as part of our successful quality systems. The manual will provide you with orientation to perform the jobs properly, and facilitate consistency in the quality and integrity of our products by the Food Act 2014.

Task 1

Food Control Plan: Food Flow Chart and CCPs Operating Procedures代写

You will be using this plan to identify risks and show how they are being managed. It is important to note that if you work to provide safe food to customers, they will be satisfied and will come back, and hence, Green Bean Café will be successful.

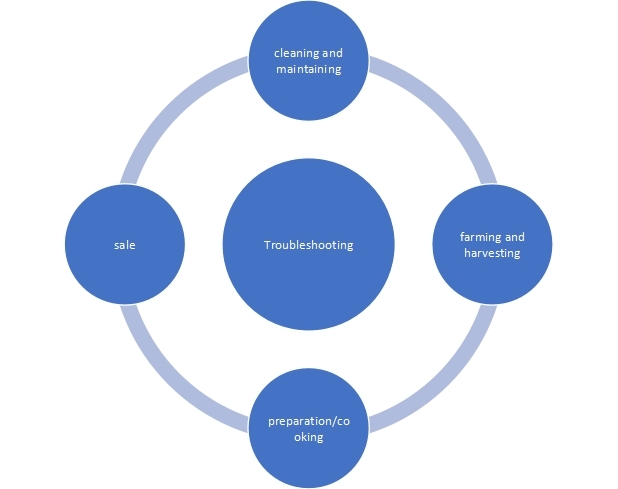

Therefore, the food flow chart is used to show how foods are prepared and delivered to the customer. The general food flow chart for Green Bean Café will follow the following steps.

General Cycle in Food Making

Step 1: Setting up

i. Learn about Green Bean Cafe

ii. Orient yourself with the café layout

iii. Ensure you manage any risks

iv. Be responsible

v. Learn about equipment

vi. Cross-checking the working plan

vii. Training and competency

viii. Ensure clean water

Step 2: Cleaning and Maintenance Operating Procedures代写

i. Ensure personal cleanliness

ii. General cleaning

iii. Facility and equipment maintenance

iv. Ensure no pests

Step 3: Food Preparation

i. Designing food preparation process

ii. Prove the method of preparation is proven to work

iii. Source the resources for food preparation

iv. Food separation

v. Maintaining optimum food temperature and pH

vi. Protecting foods from foreign matters

Step 4: Sales Operating Procedures代写

i. Ensure you know the ingredients in your food

ii. Pack and label the food

iii. Ensure safe storage and display

Step 5: Troubleshooting

i. Always cross-check if something is wrong

ii. Respond to customer response

iii. Replace damaged products

CCPs

Below is the flow chart you can use to reduce, eliminate, or prevent any contamination in foods. You should make sure you ask questions in each of the steps to decide food control.

Examples of Food Hazards and Corrective Actions Operating Procedures代写

Microbiological:

It refers “to the non-intended or accidental introduction of microbes such as bacteria, yeast, fungi, virus, prions, protozoa, and their toxins and by-products” (Bereda, Emerie, Reta, & Asfaw, 2016; Australian Institute of Food Safety, n.d). These microbiological contaminants can be controlled by maintaining hygiene. As a worker, you should make sure you observe the following hygiene, storage, packaging, and preservations procedures, and controls.

i. Ensure your main temperatures are under 5 Celsius. It will prevent the growth of harmful pathogens and control their multiplication.

ii. Ensure foods are always covered to prevent foreign matters from entry.

iii. Ensure cleanliness in all equipment

Chemical: Operating Procedures代写

Foods are likely to be contaminated by “heavy metals, polychlorinated biphenyls (PCBs), polychlorinated dibenzodioxins and dibenzofurans, DDT, Aldrin, dieldrin, heptachlor, mirex, chlordane), brominated flame retardants, pesticide residues, veterinary drugs residues, and more” (Chabukdhara, Munjal, Nema, Gupta, & Kaushal, 2016; Carvalho, 2017; Mastovska, 2013). These chemicals are harmful to humans and can lead to a slow death. Below are the steps to ensure chemicals do not contaminate the foods.

i. Packaging should be proof from damages to avoid entry of contaminants

ii. Get rid of damaged goods, equipment, and other packaging materials by either recycling them or burying.

iii. Utensils and equipment should be in good condition and regularly clean them to get rid of contaminations

Physical: Operating Procedures代写

These include physical spillage or damages of foods by objects, animals, or people (Webb & Morancie, 2015). Although these may not be harmful, they damage the structure of prepared foods. As a result, the food may not be attractive to the customer or be labeled as reject. Below is the way you can prevent physical damages of foods.

i. Safe storage away from mechanical shocks which may damage the structure, for instance in cakes

ii. The storage facilities should be tamper proof by unauthorized personnel

iii. Maintain equipment to ensure they are in good condition when working with them

iv. Always ensure foods are labeled to know their expiry dates. Always dispose of expired foods.

Personal Grooming Operating Procedures代写

Always make sure you observe grooming standards in Green Bean café. You need to keep yourself clean and professional by paying attention to the following.

i. Wear your work uniform

ii. Make your hair neat by cleaning, trimming, and combine it

iii. Make sure your make-ups (for women) are not too much and looks natural

iv. Ensure fingernails are neat, clean and trimmed

v. Make sure your breath has a fresh odor and avoid alcohol, coffee, and tobacco

vi. If you apply perfume or colognes don’t not overdo or none at all

vii. Facial hair (for men) should be freshly shaved, mustache or beard neatly trimmed

viii. Be healthy by visiting doctor regularly for check up

Steps for Washing Hands Hygienically Operating Procedures代写

Make sure you wash your hand before, during, and after preparing foods. Below are steps in hands hygienically.

i. Wet your hands before applying soap

ii. Rinse your hands together palm to palm

iii. Rub the palm of one hand along the back of the other

iv. Interlock your hands to push and pull the hands to clean the sides of the fingers

v. Rub palm to each other to ensure they are clean

vi. Rinse your hands thoroughly and dry them with a disposable towel

References Operating Procedures代写

Australian Institute of Food Safety. (n.d). Food safety and the different types of food contamination. Retrieved from https://www.foodsafety.com.au/resources/articles/food-safety-and-the-different-types-of-food-contamination

Bereda, T. W., Emerie, Y. M., Reta, M. A., & Asfaw, H. S. (2016). Microbiological safety of street vended foods in Jigjiga City, Eastern Ethiopia. Ethiopian journal of health sciences, 26(2), 163-172.

Chabukdhara, M., Munjal, A., Nema, A. K., Gupta, S. K., & Kaushal, R. K. (2016). Heavy metal contamination in vegetables grown around peri-urban and urban-industrial clusters in Ghaziabad, India. Human and Ecological Risk Assessment: An International Journal, 22(3), 736-752.

Carvalho, F. P. (2017). Pesticides, environment, and food safety. Food and Energy Security, 6(2), 48-60.

Manning, L. (2018). The value of food safety culture to the hospitality industry. Worldwide Hospitality and Tourism Themes, 10(3), 284-296.

Mastovska, K. (2013). Modern analysis of chemical contaminants in food. Food Safety Magazine. Available online at: http://www. foodsafetymagazine. com/magazine-archive1/februarymarch-2013/modern-analysis-of-chemicalcontaminants-in-food/(Accessed on 21 Aug, 2017).

New Zealand. (2014). Food Act 2014 [ebook]. Retrieved from http://extwprlegs1.fao.org/docs/pdf/nze152728.pdf

Webb, M., & Morancie, A. (2015). Food safety knowledge of foodservice workers at a university campus by education level, experience, and food safety training. Food Control, 50, 259-264.

Wellington City Council. (n.d). Food control plans & national program. Retrieved from https://wellington.govt.nz/services/consents-and-licences/food-safety/food-sellers/food-control-plans